Our purpose is to help create lasting legacies

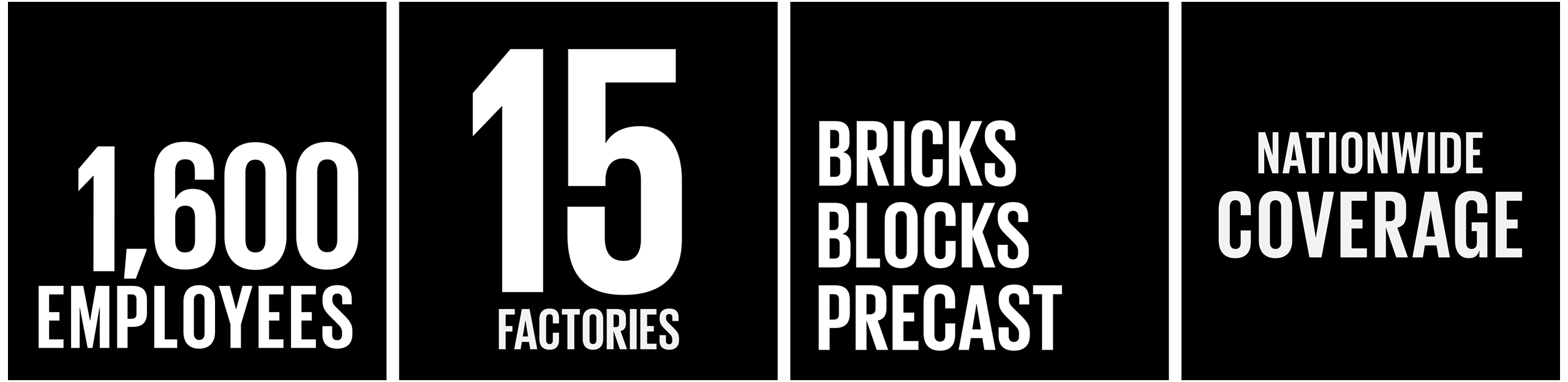

From our 15 manufacturing sites our 1600 employees create the bricks, blocks, precast concrete, paving and many other vital products and services that enable the development of thriving communities and infrastructure.

Our expertise lies in building products made from clay and concrete, and our portfolio contains some of the most recognised and respected names in the construction industry. Some of them, such as London Brick and Butterley, date back to the 19th century while others, such as Ecostock and Formpave, are far more recent; but whether historic or modern, traditional or cutting edge, they all have the needs of the 21st century at core.

New product development: helping improve construction through innovation

With construction sites under pressure to meet schedules while battling the British weather and, most importantly, keeping workers safe, we are using our knowledge, founded upon a rich heritage in clay brick and concrete manufacture, to meet the needs of modern methods of construction.

Using a Design for Manufacture and Assembly (DfMA) approach, we have developed a range of offsite walling and façade systems such as Bison Precast’s brick-faced sandwich panels, which are made by factory-fitting brick finishes onto precast concrete panels. Because they can be manufactured with any clay facing brick from the Forterra range cast in, they are an obvious choice for architects and developers looking to achieve a nice aesthetic and speed of construction without the worry of a shortage of on-site trades or material supply.

Find out more about Forterra’s façade systems

Sustainability

The products we manufacture are inherently sustainable, creating structures that last for generations. They are durable, require little or no maintenance and can be recycled at the end of their use. Our brick, block and precast products also contribute to thermal mass, resulting in buildings that need less energy for heating and cooling. Read about the significant work we are doing to make our business and products even more environmentally responsible.

Read more about our approach to Sustainability.

MANUFACTURING EXCELLENCE

Our senior team come from diverse backgrounds and industries. Collectively, they bring together the best tools and techniques to make Forterra a better and more efficient business, so we are in a strong position to understand and fulfil the needs of our customers and the wider construction industry.

Using developments from the aerospace industry, for example, we have begun the introduction of smart, intelligent, computer systems that track and trace products so we can provide customers with real time feedback.

Intelligent computer systems are also helping us to improve productivity and output by prompting operators when action is required. It all means that we are better able to get product to customers when they want it.