Brickwork specification – Details matter

Getting the brickwork specification right will create a design statement that will help your property development sell faster. In this second blog, we get Billy Mavropoulos from Bureau de Change to tell us get how to get the details right to add that extra “wow” factor.

Having chosen your brick colour and texture – see blog “Make your Building Stand Out – A Guide to Brickwork Specification” – we take a look at how you can begin to mix it up to see how different bond patterns and mortars can make your building stand out from the crowd.

Brick bond patterns

How you lay your bricks will affect its structural stability and strength but can also add aesthetic appeal and a note of subtle difference. Below are the five most common bonding patterns that you will come across in the UK:

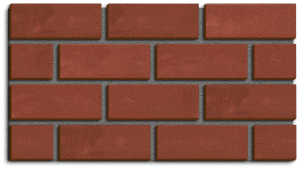

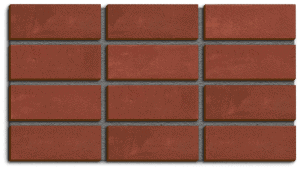

Stretcher bond

Let’s start with the most familiar, the stretcher bond. This is the most economical bond and is the most commonly used for single skin modern buildings. And because you use mostly full bricks it reduces cutting and waste and improves laying efficiency.

Design tip: It’s familiar, uniform and you can use it in and around historically sensitive sites.

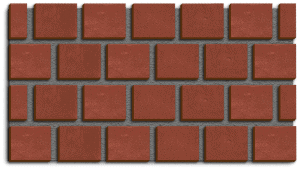

Header bond

This is a historical and very strong bond that exposes the header face of the brick.

Design tip: It offers you more design flexibility for creating curved form works than the stretcher bond, while still offering the same rhythm.

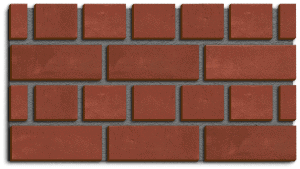

English bond

Okay let’s begin to mix it up a bit now; the English bond uses alternative courses of headers and stretchers in which the headers are centralised with the mid-point of the stretcher. This gives you a very strong bond, which is why it’s often used for civil engineering structures such as bridges or embankment walls.

Design tip: For something different why not select different textured or coloured bricks to emphasis the break in continuity?

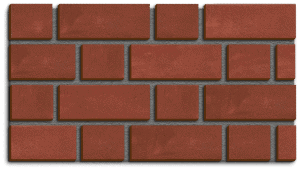

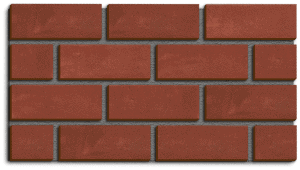

Flemish bond

The Flemish bond continues in the same vein of mixing it up a bit. This time the headers are centralised with the mid-point of the stretcher on the course below and above. Traditionally builders would construct walls that were one full stretcher in width, but in modern times this bond uses a single skin, or half brick, by introducing snap headers or bats.

Design tip: This decorative bond lends a visual patterned regularity. Try adding alternative texture or colour headers to achieve a chequered effect.

Stack brick bond

This is a modern and contemporary bond where the bricks are vertically or horizontally stacked – they do not overlap from course to course. A word of warning this gives a weak bond which you will need to compensate for with bed reinforcement and increased wall tie frequency – we would advice you to speak to your structural engineer.

Design tip: Perfect vertical and horizontal alignments allow you to focus on the bricks’ design and qualities. Specifiers often use them for feature walls and rain-screens.

The Role of Mortar in Your Design

While you spend a lot of time choosing the right brick for your development, it’s worth remembering that mortar makes up about 17% of a wall. It is vital that you do not overlook its impact on your overall scheme.

Mortar colour

Different mortar colours are achieved using a combination of coloured sands and cements,

although ready-mixed coloured mortars are also available.

Here are some mortar and brick combinations to think about:

Mortar design tip 1: Darker mortars with lighter colour bricks can help emphasise the brick itself – whether it be the unique colouration or surface texture treatment.

Mortar design tip 2: Dark mortars with dark colour bricks create a balanced and cohesive appearance.

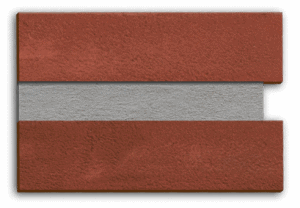

Mortar design tip 3: Lighter mortars with darker colour bricks can highlight the vertical and horizontal lines to show off the brick bond pattern.

Mortar design tip 4: You can use light mortars with light-coloured bricks to create a surface that easily interacts with light to punctuate and highlight selected textures.

Mortar joint profiles

While they are important for improving rain resistance you can also use the shape and finish of mortar joints to create as big an impact on the brickwork appearance as its colour. Here are five of the more common examples:

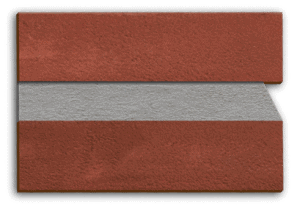

Flush mortar joint

These joints leave the mortar flush with the surface of the brickwork.

Design tip: Try using this mortar joint with coloured mortar to create colour differentiation on a relatively even surface.

Bucket handle mortar joint

These joints are tooled to leave a concave, rounded joint.

Design tip: When you pair this joint with smooth faced bricks, it creates a straightforward and eye pleasing finish to the surface.

Weathered struck mortar joint

These are created by pressing the mortar back into the brickwork to seal the joint. This joint will also shed water from the mortar lines to help preserve the surface’s longevity.

Design tip: This joint gives a neat well-ordered appearance that looks best with well-formed regular bricks.

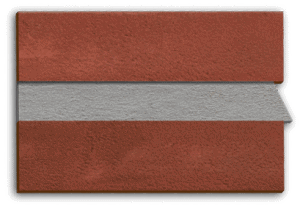

Weathered struck and cut mortar joint

You form these joints as pointing with the inset edge produced in the same way as the weathered struck joints, but the forward edge projects about 2mm beyond the brick surface.

Recessed mortar joint

This joint type is raked out to leave the brickwork exposed.

Design tip: By creating a shadow effect this joint can help pick out individual bricks.

But note: This joint is not generally recommended by brick manufacturers for external walls due to the increased exposure it creates on the brick.

Conclusion

The secret of exquisite brickwork design lies within careful detailing. There are numerous brick colours and textures and when you combine these with different construction methods, arrangements and mortars the possibilities to create something remarkable are endless.

Billy Mavropoulos is a founder of the award-winning architects practice Bureau de Change. In 2019 the practice was awarded the Sunday Times Architect of Year award and it was shortlisted for the RIBA Awards in 2020. If you need some advice or help with your next development then email Bureau de Change at: bureau@b-de-c.com

To see the 100s of different bricks that Forterra manufacture, take a look at our Product Selector page. If you are trying to match a brick for an existing installation or to match the local surroundings then take a look at our brick matching service.

Brickwork Specification – Details Matter

This blog contains some of the content from our CPD seminar Materials Specification and Workmanship. To test your understanding and receive your certificate simply answer the following questions:

Note our CPD on material specification also covers the different types of brick manufactured in the UK, BS EN 771-1, brick properties and technical details such as the placement of movement joints. To sign up for this CPD click here.